New Products

Find Variable Frequency Drive For Centrifugal Pump, VFD For Pump, Ac Variable Frequency Drive For Pump on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Model No.: VFD

Variable Frequency Drive For Water Pump

In many factories in the industrial field, these pumps, such as Submerged Pump,Process Water Pump,Lye Pump,Single Casing Pump,Dredge Ash Slurry Pump,Sand Suction Dredge Pump,Sand Slurry Pump,Flotation Machine Feeding Pump,Mine Slurry Pump,Froth Pump etc., make up piping system with motor, pipeline and Other equipments. Due to the diversity of piping system layout and the special requirements of production process, there are often the following conditions or problems: (1) the pipeline outlet pressure changes with the process pressure difference; (2) the pipeline transportation distance varies with distance change; (3) pipeline conveying height changes with height difference; (4) seasonal variation or high and low peak time difference variation; (5) the reserved margin of pump performance parameters is too large, causing the pump deviation from the design point in application.

The traditional solutions include adjusting the discharge line valve, hydraulic coupling speed regulation, variable pole motor speed regulation, motor series pole speed regulation, etc. However, they all have the shortcomings of low efficiency, small adjusting range, slow speed, poor adjusting performance and many faults. At present, the most effective and popular method of adjusting pump speed is frequency conversion control method. Practice tells us that it is possible for VFD to save 20-30% of the system's energy.

1. The basic principle of Variable Frequency Drives (VFD)

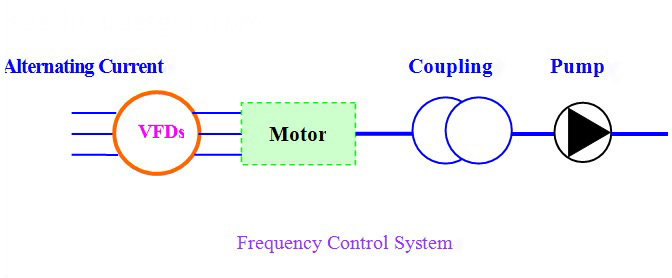

The relationship between speed n and electrical frequency of the power supplied f, the number of magnetic pole pairs p, slip rate s of asynchronous motor is n=60f(1-s)/p. When the slip rate s does not change much, the speed n of the asynchronous motor is basically proportional to the frequency f, and the speed of the motor can be smoothly changed by continuously adjusting the frequency. AC speed regulation realized by the inverter generating the variable frequency and variable voltage AC power supply to the AC motor is called Variable frequency drives.

Variable frequency drives are a typical method of ac motor speed regulation, which is not only suitable for asynchronous motor, but also suitable for synchronous motor. Variable frequency speed regulation has the advantages of continuous adjustable frequency, stepless speed regulation, large range of speed regulation, hard mechanical characteristics, superior stability of speed and high-efficiency.

Figure 1. Frequency Control System

2. Application of VFD technology in water pump

2.1 Working principle of water pumps

According to fluid mechanics theory, the pump flow rate Q, head H, shaft power P,rotational speed n has the following relationship: flow rate Q is proportional to the rotational speed n, head H increases with the square of the speed n; shaft power P increases with the cube of the speed n.

2.2 The effect of pump speed regulation

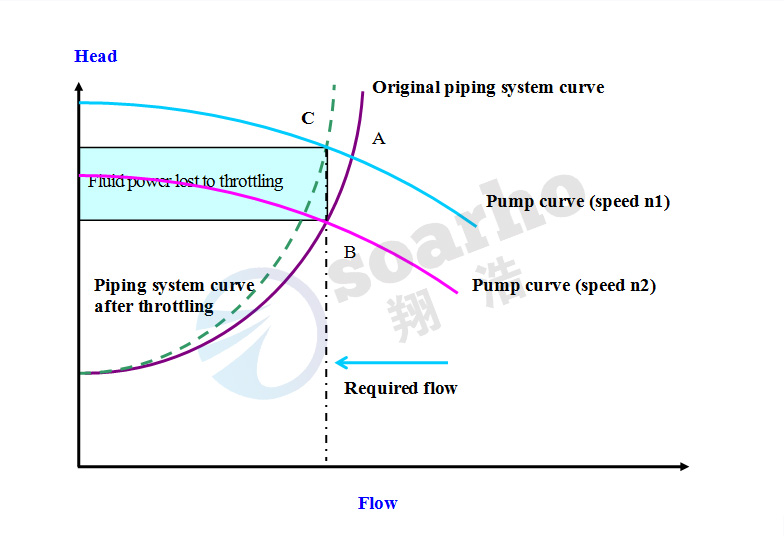

When the pump curve intersects with the piping system curve, the intersection point is its working condition point, as shown in Figure 2 for A and B points. If the pump runs at a certain constant speed, the flow can only be adjusted by the outlet valve. When the flow decreases, the pump head moves upward with the curve, as shown in Figure 2, A and C. At this time, the adjustment of the valve is equivalent to increasing the pipe resistance loss to achieve the effect of reducing the flow and the outlet pressure of the pipe end. In this way, the reduction of motor shaft power is limited.

By changing the speed of the water pump, that is, the pump speed is adjusted from n1 to n2, the pump operating point is slid from the point A in the figure 2 along the piping system curve to the point B. It can be intuitively concluded that the flow rate and head are reduced accordingly. As shown in Table 1, if the frequency is reduced by 5Hz, the speed will decrease by 10%, the flow will be reduced by 10%, the head will be reduced by 19%, and the motor power will be reduced by 27%. When the frequency is reduced by 10Hz, the speed will be reduced by 10% and the flow will be reduced. 20%, the head is down 36%, and the motor power is down 49%. The effect of frequency conversion regulation and energy-saving is very significant.

Table 1. Frequency adjustment power change table

| Frequency reduction(HZ) | Flow reduction % | Head reduction % | Power reduction % |

| 2 | 4% | 8% | 11.5% |

| 4 | 8% | 15% | 22.1% |

| 6 | 12% | 23% | 31.9% |

| 8 | 16% | 29% | 40.7% |

| 10 | 20% | 36% | 48.8% |

| 12 | 24% | 42% | 56.1% |

| 14 | 28% | 48% | 62.7% |

| 16 | 32% | 54% | 68.6% |

| 18 | 36% | 59% | 73.8% |

| 20 | 40% | 64% | 78.4% |

2.3 Notices for VFD of Water Pumps

2.3.1 Pump speed regulation should adapt to the change in working conditions, and make the pump always working in the high efficiency zone, because any point on the pump curve can be changed into another working condition according to the similarity theorem after speed regulation. Selecting the working point in the operating point of the high efficiency zone of the pump curve or the working condition point obtained by the similarity conversion of the high-efficiency zone enables the pump to operate efficiently and achieve the purpose of energy saving

2.3.2 Pump speed adjustment is not suitable for all systems. In applications with high static head, slowing a pump risks inducing vibrations and creating performance problems. For systems in which the static head represents a large portion of the total head, caution should be used in deciding whether to use VFD.

3 Combination of VFD and PMSM is a new energy saving application trend

Today, design engineers and equipment owners are beginning to install more permanent magnet motor solutions for pump applications because they are smaller and more efficient. We have designed a new VFD control program that uses load matching technology to allow the motor to operate only when needed, saving energy and reducing equipment wear. The combination of VFD and PMSM is a new energy saving application trend.

4. Product feature

4.1 Saving energy

The VFD system controls the motor and automatically adjusts the motor load to make the motor run in an economy running state to achieve the effect of power saving.

4.2 Lower operating costs

The system can greatly reduce the energy cost of the motor, reduce the impact on the equipment after the frequency conversion start, and reduce the maintenance and repairing capacity, so the operation cost will be greatly reduced.

4.3 Improve pressure control accuracies

Variable frequency control system has accurate pressure control ability, which effectively improves the quality of the system working condition.

4.4 Extend the service lives of the motor

From the 0Hz starting motor, the starting acceleration time of the inverter can be adjusted to reduce the impact on the electrical and mechanical components of the motor when starting, so as to enhance the reliability of the system and prolong the service life of the motor. In addition, the frequency converter can effectively reduce the peak value of starting current to a minimum, and can reduce the impact on the grid and other electrical equipment.

4.5 Extend pump life

For the slurry pump which delivering liquids with particles, the service life of the wet parts of the pump is inversely proportional to the cubic of the pump speed. If the speed is reduced by 10%, the service life will be increased by 30%.

4.6 Reduce the noise of the motor

According to the working condition of the motor, the motor running speed is slowed down obviously after the frequency conversion speed adjustment is installed, so the noise of the motor running is effectively decreased.

Product Categories : Energy Saving Products Matching With Pump > Variable Frequency Drive For Pump